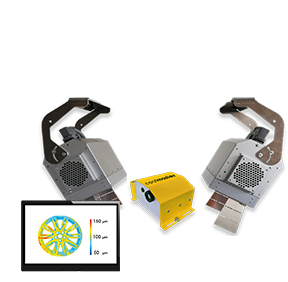

Paint Thickness Gauge: Precise measurements are possible even before drying

Wet paint coatings perform functional tasks that depend on the coating thickness. The conventional test equipment for monitoring the layer thickness does not do justice to their task here, because the layers are destroyed by the measuring process and because these tests have a low repetition accuracy.

coatmaster paint thickness gauge can measure the wet paint coating thickness on painted parts before drying. This enables process deviations to be detected at an early stage. This saves material costs, minimizes the production of faulty coated parts and optimizes quality because narrow tolerance windows are exactly maintained. It is also possible to measure the paint coating thickness even if the coating has already dried.